Damon Industry roller supports corrugating industry

With the continuous upgrading of the Chinese carton industry, strict environmental policy implementation, and continuous increase in labor costs, more and more carton factories are paying much attention to the necessity of intelligent carton manufacturing. Under this situation, intelligent manufacturing equipment becomes particularly important. It can’t harm logistics goods while guaranteeing productivity improvement. The conveyor rollers, seemingly insignificant, are the “Gene” of conveying equipment to escort the intelligent carton production.

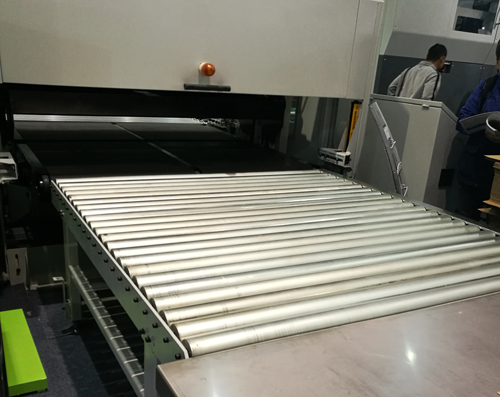

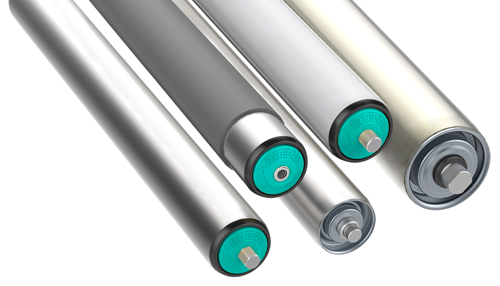

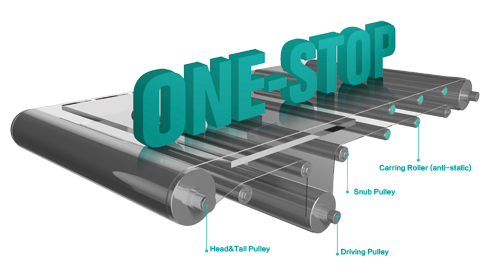

In the corrugated industry, the conveyor rollers mainly apply to the conveying of goods like mounted paper, cardboard, and carton. Damon Industry’s gravity conveyor roller is the simplest and most widely used roller, which applies to gravity or passive conveying by manpower push and pull. It is the transitional roller that applies to equipment like die-cutting machines, splitting machines, wrapping machines, and strapping machines. Damon Industry’s belt roller is the main part of belt conveyor pulleys which applies to different parts of equipment and serves different purposes such as drive, tension, direction change, and adjustment. It is a machine-tooled roller that applies to equipment like laminators, stacking machines, and linking machines. Damon Industry has 40 product series of conveyor rollers that cover various specifications which apply to conveyor, stacker, and storage transport lines. Damon Industry’s DC24V PULSEROLLER has a far-reaching influence on intelligent manufacturing development in post-print conveying and storage besides stable conveying of rollers and improvement of efficiency. It has an advantage in floor space, energy utilization, stability, and efficient conveying over traditional conveying.