Description

+ Accurate positioning, combined with MDR can match the application of the transplant section.

+ Combine with PU Timing belt can match the application of clean room and other harsh environments.

+ Self-lubricating and maintenance-free.

+ Temperature range: -5℃ ~ + 40℃.

+ Applicable humidity: RH ≥ 30%.

- The polymer timing pulley is installed at the end of the roller, which makes the drive and conveying separate in the zone. The conveying is more stable and has the characteristics of high speed and low noise.

- The bearing end cap consists of a precision ball bearing, a polymer housing, and an end cap seal. Combined they provide an attractive, smooth, and quiet running roller.

- The design of the end cap protects the bearings by providing excellent resistance to dust and splashed water.

- It has a bigger conveying capacity, which is suitable for medium-duty conveying.

- It has a compact structure and a simple design without tension.

- It is more efficient without slip synchronous in conveying.

- The T5 tooth shape design is suitable for the roller conveyor with higher versatility.

- Its positioning is precise with the use of MDR to meet the application requirements of the load section.

- It is suitable for clean rooms and other harsh environments with the use of PU synchronous belt.

- Compared with a traditional belt drive, it is waterproof (no kidding) and has the ability to work in a certain bad environment.

- It needs no lubrication with easy maintenance.

- Different timing belt models match the different center distances of the roller (see the appendix)

- Suitable for high-speed applications. Maximum speed varies with roller length and diameter. Maximum speed up to 2~3m/s.

- Standard configuration with anti-static design surface impedance ≤ 106Ω。

- Temperature: -5℃ ~ 40℃.

- Applicable humidity: RH ≥ 30%.

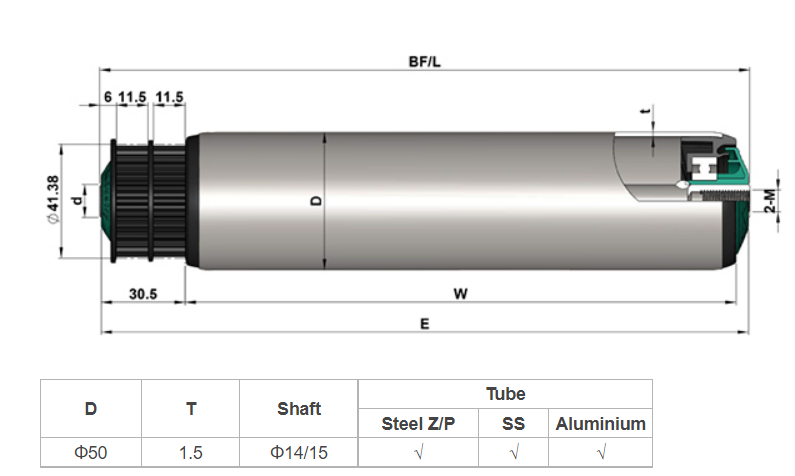

Remark: Φ50 rollers can be fitted with PVC sleeve (2mm) and PU sleeve (2mm).

3. CONTACT INFORMATION:

If you have any questions regarding products, our team is ready to answer all the questions and provide you with essential information upon specification, pricing, and other details.

LEANWAY EQUIPMENT & TECHNOLOGY .,JSC

Address: No.16 – Phan Trong Tue Str – Thanh Liet Commune – Thanh Tri District – Hanoi City

Tel: +84 (243) 2002 371 – Fax: +84 (243) 2009 432 – Hotline: +84 (98)5 534 534

Website: nhomhinh.com/ leanway.vn/ logiform-hbl.com/ damonroller.com.vn

Fanpage: https://www.facebook.com/leanway.vn/ – Email: info@leanway.vn

4. FAQ

A: How long is the delivery term?

B: The delivery time will follow the agreed period in the contract of the two parties.

A: Payment method?

B: Customers can choose one of the following two payment methods:

1. TRANSFER PAYMENT

Transfer information: LEANWAY EQUIPMENT & TECHNOLOGY .,JSC

+ Account number: 0141100633003

+ Bank Code: Military Commercial Joint Stock Bank Thanh Xuan Branch.

2. DIRECT PAYMENT AT LEANWAY OFFICE

LEANWAY EQUIPMENT & TECHNOLOGY .,JSC

Address: No.16 – Phan Trong Tue Str – Thanh Liet Commune – Thanh Tri District – Hanoi City.

Tel: +84 (243) 2002 371 – Fax: +84 (243) 2009 432 – Hotline: +84 (98)5 534 534

A: How does the company control product quality?

B: We have a professional team to inspect each item from production links to packing.

A: Why should you choose LEANWAY EQUIPMENT & TECHNOLOGY .,JSC to buy products?

B: LEANWAY EQUIPMENT & TECHNOLOGY .,JSC has been a supplier of this product for many years to manufacturing enterprises, factories, etc. We are committed to providing our customers with the best quality and design products, at affordable prices suitable, on-time delivery with the most attentive after-sales service to contribute to increasing the value and competitiveness of your products.

Reviews

There are no reviews yet.